This past June, I, along with a few other outdoor journalists, was invited to visit the Buck Knives manufacturing facility located in Post Falls, Idaho. We flew into nearby Spokane, Washington, and were met at the airport by Buck rep. Mike Faw, and driven to our lodgings in Post Falls. The following two days, we were treated to the full Buck Knives experience.

The Buck Knives Red Carpet

On the first day, we were at the factory, where we had introductions. This was followed by a company history, an overview of Buck products, and then a guided tour. At the end of the day, we tried hand-sharpening a knife blade and then assembled a knife from its parts.

The next day was a real surprise, as we were taken to the St. Joe River. Once there, we boarded Drift Boats and did some fly-fishing for trout.

Advertisement — Continue Reading Below

Back to the Beginning

I had always assumed that the “Buck” in Buck Knives was just a cool name marketing-wise for a hunting knife. Not so. In 1902, a young apprentice blacksmith named Hoyt Buck made his first knife in Leavenworth, Kansas. He discovered a way to heat-treat the steel in worn-out files, buggy springs, and old grubbing hoes. The result was knife blades that would hold an edge.

Five years later, he was still living in the northwest and making knives on the side. Two years later, he married and had a son, Alfred. By 1912, he had relocated from Tacoma to Everett, Washington. Soon after, another son, George, came along.

By 1927, Al had grown up, joined the Navy, and was sent to San Diego, California. After his stint, he rejoined his family in Washington. However, in 1932, Al and his brother George joined the Coast Guard.

Advertisement — Continue Reading Below

Al married in 1933 and again ended up in San Diego. He left the Coast Guard in 1935, bought a small house, and got a job with a meatpacking company. In 1936, he had a son of his own—Chuck.

The Buck’s Move to Idaho

Meanwhile, in 1937, Hoyt and his wife Daisy moved to Mountain Home, Idaho, where he took a job as a millwright. Al moved to a new house, with a small garage, at 1272 Moreno Blvd. in San Diego in 1940.

Advertisement — Continue Reading Below

Hoyt had continued in his hobby of knife making. However, on December 7, 1941, his part-time enterprise took more of his time as his rugged knives became popular with G.I.s. By 1942, Hoyt bought a forge, anvil, and mandrel and created a new fixed-blade knife that later became the 119 Special.

By this time, Al is a bus driver for the San Diego Transit Co. With knife orders on the rise, in 1945, Hoyt moves to San Diego, where he and Daisy live with Al and family. They set up a knife-making shop in a lean-to built on the side of Al’s garage. Al joins Hoyt, making knives, and they form H.H. Buck & Son, making and selling knives, mostly by mail order.

The Birth of “Buck Knives”

By 1947, they had to build a second shop by the garage and start buying print ads in outdoor magazines. But in 1948, Hoyt was diagnosed with cancer. He moved back to the Pacific Northwest and passed away in Spokane, Washington, in 1949.

Advertisement — Continue Reading Below

During the 1950s, Al kept Buck Knives going with family members. In 1961, the company became Buck Knives, Inc. Manufacturing moved to a small facility in Los Angeles, and they began to use forged steel blanks to make knives, speeding up production. They also started to use black phenolic resin for knife handles, creating the distinctive Buck look.

Knife history was made in 1963 when Buck introduced the Model 110 Folding Hunter. Now, outdoorsmen can have a compact folding knife with a lock-blade that’s as strong as a larger fixed-blade knife. This knife became a milestone and remains Buck’s best seller to this day.

Advertisement — Continue Reading Below

Fast forward to the 1970s and 80s. Buck added to their product line and moved to a state-of-the-art facility in El Cajon, California. 1987 saw Buck designing the M9 Bayonet for the U.S. Army and introducing a titanium knife.

Al passed away in 1991, but Buck Knives continued to grow, with Chuck Buck at the helm. With growing product lines, Buck again relocates, this time to a large manufacturing plant in Post Falls, Idaho. The company, which began with a single handmade knife crafted from a file over 123 years ago, is now one of the largest and premier knife-makers worldwide. In fact, this year marks the 20th Anniversary of Buck Knives in their Post Falls facility.

How They’re Made

The Buck Knife factory is a 130,000-square-foot facility. It includes manufacturing floor space, headquarters offices, a museum, and a retail store. Some 320 employees work out of the plant at 660 South Lochsa Street, near the banks of the Spokane River.

Advertisement — Continue Reading Below

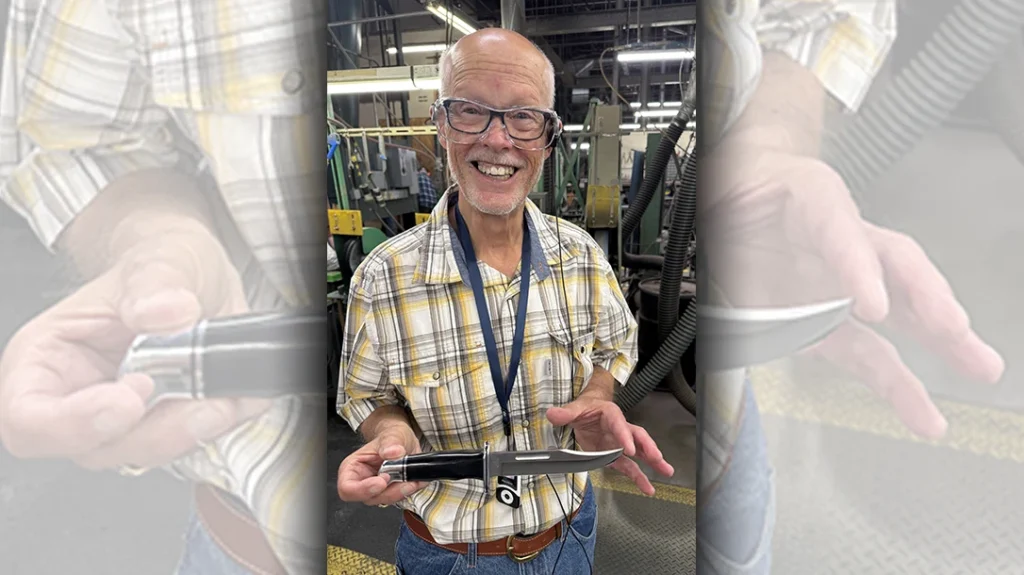

From what I saw during my tour, it looks like a great place to work, and some of the personnel have been with Buck for over 40 years. This work requires considerable skill, and it usually takes about three years for an employee to become fully trained.

Much of the knife assembly work is done by hand. They even sharpen the knives by hand, one by one. This is one reason that quality Buck Knives have a “Forever Guarantee.”

Today, the knives start out as rolls of made-in-the-USA steel. The various blade types and sizes are punched out. The leftover steel sheets have become popular sales items; some are used for BBQ grills.

Advertisement — Continue Reading Below

Next comes the heat treatment. It’s an exclusive process utilizing the practices of Paul Bos. Other companies also contract Buck for its heat-treating service.

Next, experienced employees take the various parts—handles/scales, pommels, bolsters, guards, and blades—and assemble the knives. They also do hand-finishing. Buck also has a custom shop, where customers can order a knife to their specifications, including special markings, handle material, and other embellishments.

Advertisement — Continue Reading Below

The final step is sharpening, and, as I mentioned earlier, this is done by hand. A skillful sharpener can make a blade razor-sharp, usually in less than 30 seconds. Buck also has a lab where the knives are subjected to rigorous testing to ensure they are reliable and can withstand the demands of hard use.

The Range Series

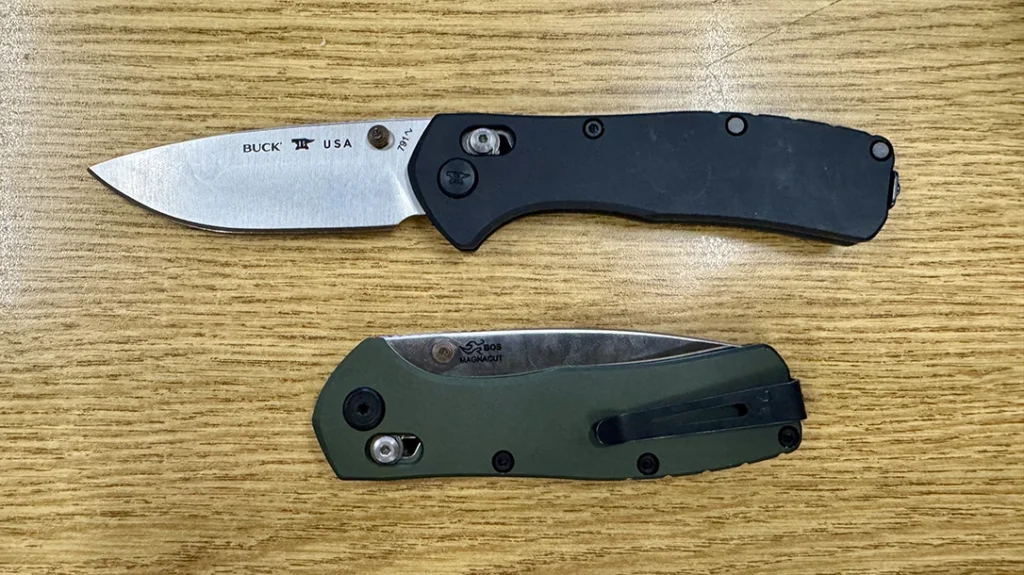

During our initial classroom session, we were introduced to a new product line that will be launched in August 2025. It’s called the Range Series.

These slender, lightweight, lock-blade, folding knives are meant for EDC. The blades are Magnacut or 154CM steel, with a flat grind and drop-point. They feature easy one-hand opening via a thumb stud or manipulation of the crossbar lock, and flicking open the blade. It also has a reversible deep carry pocket clip.

Two models are available: the Elite and Pro, as well as mini versions. The primary differences are the type of blade steel, handle material, and size. The anodized aluminum or GFN Polymer handles can be had with a dark gray, OD green, or black finish.

All are BOS heat-treated and, of course, carry the Buck Forever Warranty. MSRP runs from $124 to $275.00, depending on the model selected.

As I mentioned earlier, we got to build our own Range Elite series knives from parts. All the participants were given parts kits, and then, one by one, were tutored on how to assemble the knife.

An ingenious die block was used to hold the parts in place as, step-by-step, we completed the assembly process. Now I’m not “Tim the Toolman,” but my instructor complimented me on the speed and precision of my knife construction.

I chose the OD Green handles, and this knife is sitting on the desk beside me as I complete this article. The Buck staff congratulated us as we all managed to put our knives together with no cut fingers.

A Buck Knives Believer

I’ve been a “Buck Believer” for many years, and my own first hunting knife was a Model 110 Folding Hunter. I was impressed by the manufacturing process and the care that goes into the making of each knife. It was also refreshing to see dedicated employees who take obvious pride in their jobs. Not to mention, the entire staff seems like one big family.

No matter what kind of knife you need, hunting, fishing, camping, EDC, or even kitchen use, Buck Knives has the knife for you. And you can count on that knife being top quality, durable, solid, and sharp. Besides that, Buck will “back them to the hilt.”

Buck Knives 791 Range Elite Specs

| Blade | Drop point, Magnacut, 3.375 in. length, 0.090 in. thick |

| Length | 7.875 in. overall, 4.50 in. closed |

| Weight | 3.30 oz. |

| Handle | Anodized aluminum (black, green, gray) |

| Clip | Reversible pocket clip |

| Lock | Cross-bar lock |

| Features | Drop-point, satin finished blade, thumb stud, easy one-hand open/close, Made in the USA, Forever Warranty |

| MSRP | $275.00 |

WHY OUR ARTICLES/REVIEWS DO NOT HAVE AFFILIATE LINKS

Affiliate links create a financial incentive for writers to promote certain products, which can lead to biased recommendations. This blurs the line between genuine advice and marketing, reducing trust in the content.