A stumbling block for many knife users when trying to learn how to sharpen is a lack of knowledge about different grinds. This is also true when purchasing a knife for a specific task. Not all grinds are the same, and each has its own purpose. The more you understand the difference between them, the better you will be at sharpening and picking the right knife for the job.

Chisel

True to its name, the Chisel Grind mirrors a wood chisel: flat on one side, ground on the other. In theory, some argue this asymmetrical geometry offers added strength, but that claim doesn’t fully hold up under scrutiny. A single 15° grind is still just 15°. However, a conventional symmetrical edge runs 15° per side for a combined 30° edge angle. In practical use, the Chisel Grind is literally half a grind.

Advertisement — Continue Reading Below

You’ll most often find it on certain tactical knives (Emerson Knives being the most recognizable example), but the design never gained lasting traction. The reason for this is that it is hard to cut straight. That uneven grind naturally wants to walk the blade off-line, pulling cuts in an unintended direction.

Hollow/Concave

The Hollow Grind is created using a curved grinding wheel, which scoops material out of the primary bevel and thins the blade behind the edge. This geometry allows for an extremely keen secondary (edge) bevel and excellent slicing performance.

Advertisement — Continue Reading Below

A Hollow Grind always requires a secondary bevel. Without it, the edge would be razor-thin and prone to chipping or failure. When sharpness is the priority, and hard use isn’t, the Hollow Grind excels.

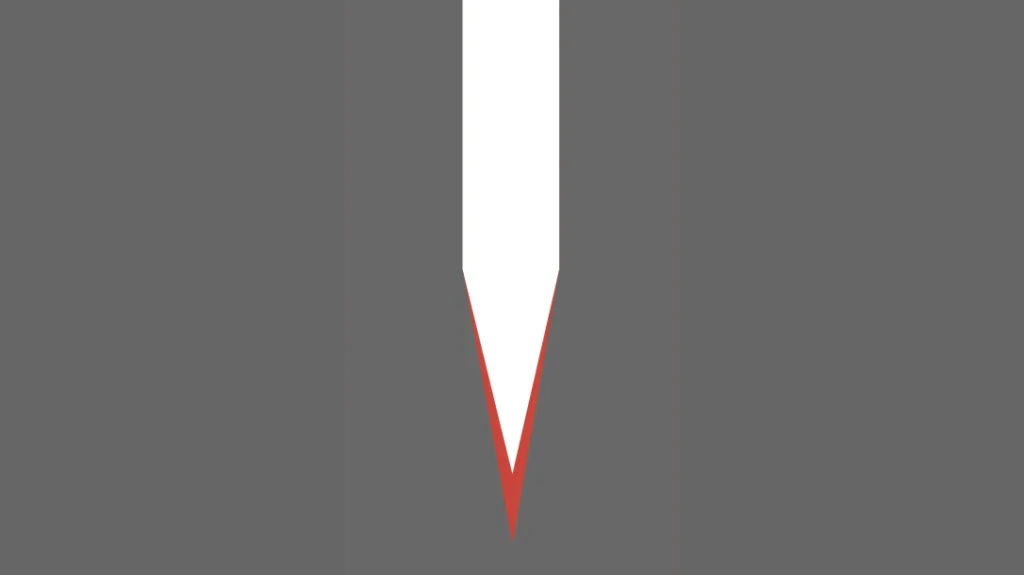

Convex

Think of the Convex Grind as the inverse of a Hollow Grind. Instead of curving inward, the bevel bows outward, leaving more steel behind the edge. That added material translates to strength and durability, often eliminating the need for a secondary (edge) bevel—though most makers still include one.

Advertisement — Continue Reading Below

The trade-off is simple physics; you won’t get the same laser-thin edge as other grinds. What you gain instead is resilience. Convex grinds shine on knives built for sustained, abusive use where edge integrity matters more than pure slicing efficiency.

Flat

Often referred to as a Full Flat Grind when it runs from edge to spine, the Flat Grind features a straight primary bevel that tapers down to a secondary (edge) bevel. This grind balances cutting efficiency with structural integrity and is one of the most versatile profiles available.

Advertisement — Continue Reading Below

Like the Hollow Grind, a Flat Grind always relies on a secondary bevel. Without it, the edge would be too thin to survive real-world use.

Saber

A common and time-tested grind, the Saber Grind also uses a flat primary bevel, but it starts lower on the blade, typically around the midpoint. This leaves more steel in the spine and produces a stronger overall blade.

Advertisement — Continue Reading Below

That strength comes at a cost. With more thickness behind the secondary bevel, cutting performance can suffer, and drag increases in dense materials. The Saber Grind favors durability over finesse.

Scandi

The Scandi Grind stands apart because the primary bevel is the edge. There is no true secondary bevel. The grind runs from the edge up toward the middle of the blade, creating a wide, flat, or convex bevel that excels at controlled cuts and fieldraft.

Advertisement — Continue Reading Below

That keen edge can be brittle under hard use, which is why many U.S. makers opt for a Modified Scandi. By adding a slight secondary bevel, they retain the Scandi’s bite while reinforcing the edge for greater durability.